Introduction To Touch Panel Bonding

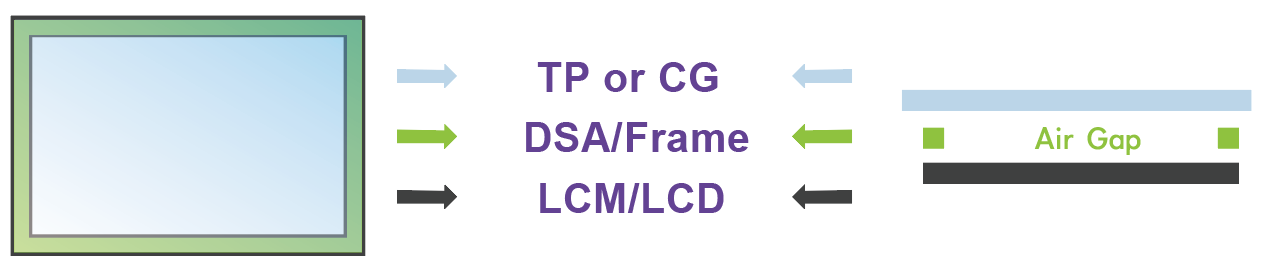

【Air Bonding】

Air Bonding process uses two-sided adhesives to bond touch panel and LCM layers together from four sides. The process would create air gap causing internal reflection leaving poor visual performance compare to optical bonding. The simple air bonding process is rather cheaper to make and is therefore an economical option.

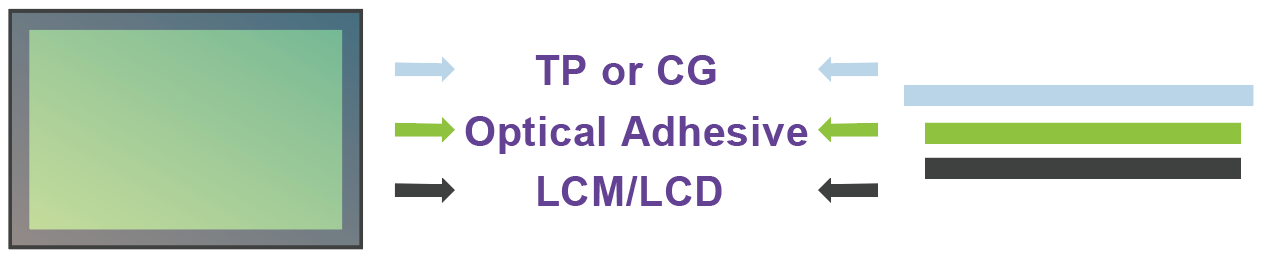

【Optical Bonding】

Optical bonding process involves attaching the cover lens onto the LCD display (carrying touch sensor) with optical adhesives, effectively filling a small air gap between them to achieve optimum sunlight readability.

Optical Bonding are categorized into:

OCA : Optical Clear Adhesive

OCR : Optical Clear Resin

【Optical Bonding method】

【The advantages of optical Bonding】

Due to a direct bonding of LCM to the touch panel, there is no air gap sandwiched in between to effectively reduce refraction of external light, dust contamination, and internal vapor condensation.

• Reduce refraction of light

• Reduce newton’s ring effect

• Strong contrast

• Eliminate dust and vapor contamination

• Reduce battery consumption

• Enhance mechanical strength and shock/vibe performance

【OCA/OCR vs Air Bonding Comparison】

OCR (Optical Clear Resin) bonding has several advantages over OCA (optical clear adhesive) bonding in:

• Flexible control over the thickness of the adhesive.

• G+LCM bonding is the best bonding solution for hard substrates.

• Best bonding solution for medium and large displays.

• Ideal solution for LCM optical bonding.

|

|

|

| Introduction to Clean Room | Touch Screen Technology Basic |